The discovery of metals has resulted in the production of many products that are part and parcel of our daily lives. Metals are used in manufacturing items such as an ordinary saucepan to space-going vessels. Individual metals tend to have certain characteristic and properties. Certain components need elements with particular properties. When a metal is unable to be suited to a particular application, it is combined with one or more elements resulting in an alloy.

Stainless steel is an example of a common alloy used in the fabrication of many products. To further strengthen the stainless steel, they are subjected to heat treatments which result in the precipitation hardening stainless steel material. One of the most used types of PH stainless steel is 17-4 PH stainless steel.

There are many things that you probably did not know about the alloy? Take heart, though. You will be amazed by how much you did not know about the most commonly used types of stainless steel. The following are seven things that you probably did not know about type 17-4 PH stainless steel:

Most Common Type of Precipitated Hardening Stainless Steel

PH stainless steels are a group of alloys that are resistant to the effects of corrosion. To increase their yield strength, these alloys are subjected to heat treatment during precipitation hardening (PH) or age hardening.

You must be wondering what all these terminologies mean. Usually, PH alloys are kept at elevated temperatures for an extended time frame. This allows precipitation to take place.

Hopefully, you remember your elementary science classes at this point. This aging or time-delayed technique tends to significantly increase the alloys yield strength.

During PH-treating, certain “impure” particles are added to the stainless steel. Such particles include elements such as molybdenum, copper, titanium or aluminum, either in combination or singly.

There are three main types of PH stainless steel, namely:

- Low Carbon Martensitic

- Semi-Austenitic

- Austenitic

Type 17-4 PH stainless steel is the most common type of martensitic PH stainless steel. At low temperatures of 250 degrees Centigrade, the martensitic alloy transforms to martensite. Martensite is basically a steel crystalline structure that is hard.

The stainless steel alloy can harden further by aging at temperatures ranging between 480-620 degrees Centigrade. The combination of the alloy’s superior properties allows it to increase product reliability while making fabrication simple and cost effective. Type 17-4 PH stainless steel has applications in industries like paper, petrochemical, aerospace and food processing. It is widely used in various general metalwork applications.

Use in Marine Vessels: Great Resistance to Effects of Corrosion

The alloy has superior resistance to corrosion and has high mechanical strength. This enables it to be used in marine applications. The fact that it is resistant to corrosion enables it to survive exposure to salty sea water.

You should know that one of the elements that confer the alloy with high resistance is chromium. Type 17-4 PH stainless steel contains between 15-17.5% of chromium in its composition. In this regard, a seagoing vessel’s pump and valve parts are made of type 17-4 PH stainless steel.

Most of the parts of that ship that you went on that annual cruise are made from type 17-4 PH stainless steel. Most of the process piping, seawater piping, and heat exchangers are made of the alloy.

Use of Type 17-4 PH Stainless Steel in Nuclear Industries

Did you know that the alloy has been used in the nuclear power generation industry? Well, what usually happens during nuclear power generation is there is the use of fuel during the process. The used fuel should be given some time to cool and be stored. Used or spent fuel from nuclear power generation is stored in a dry cask.

The dry cask is usually fabricated using type 17-4 PH stainless steel. The spent fuel in the cask has an inert gas surrounding layer. The steel cylinder cask is usually butted or welded closed. The great welding characteristics of the alloy allow this to be possible.

This design of the dry cask using type 17-4 PH stainless steel ensures that the radioactive spent fuel is in a safe storage design that is 100% leak proof. To ensure that there is adequate radiation shielding for you, in case you work in such a plant, reinforcement is achieved using extra steel, concrete or other material.

Use in Pulp and Paper Industries

To increase its strength during PH treatment, some elements are added to the stainless steel. The composition of type 17-4 PH stainless steel is as follows:

- Carbon-0.07%

- Manganese-1.00%

- Sulphur-0.03%

- Tantalum and Colombium-0.15-0.45%

- Chromium-15-17.50%

- Silicon-1.00%

- Nickel-3.00-5.00%

- Copper-3.00-5.00%

As a result of its composition and depending on the temperature, the alloys are able to develop various properties.The versatility of the alloy makes it quite popular in industries like the pulp and paper. In the past, you may have noticed that paper mills were made of materials such as carbon steel, bronze, and granite. Well, not anymore.

In the manufacture of paper, batch digesters are important pieces of equipment. What batch digesters do is they manufacture solid pulp products. The paper that you use every day to write on is then made from these pulp products. In the past, bulk digesters in the pulp and paper industry required plants to shut down at least every 18 months for routine maintenance. Currently, such bulk digesters are made of stainless steel.

You will find that stainless steel bulk digesters are much thinner than their carbon steel counterparts. This is because type 17-4 PH stainless steel has a higher yield pressure than carbon steel.

Corrosion of carbon steel digesters has been a perennial design problem. The use of type 17-4 PH stainless steel, which has a high resistance to corrosion, has been of great significant value in the paper industry. As you can see, this also reduces costs because the equipment will not succumb to the effects of corrosion and breakdown.

Turbine Blade Design

The next time you see a gas or windmill turbine at work, try and remember that it works because of the use of type 17-4 PH stainless steel in its construction.

In case you are familiar with the design of a turbine, then you are familiar with a combustor. If not, a combustor produces gas at a high pressure and temperature. It is the turbine blades that extract the energy that you need from these gasses.

As you can see, the turbine blade material should be able to withstand the harsh conditions of high heat and pressure. In the past, one of the common causes of failure in turbine blades was a stress material failure and fatigue.

Current turbine blade design makes use of super-alloys like type 17-4 PH stainless steel. The fact that the alloy has a high resistance and is able to keep its strength under adverse conditions like high temperatures makes it an ideal choice in turbine blade design.

Most plane engine manufacturers like Pratt and Whitney or Rolls Royce make use of the alloy when designing the turbine blades for their massive engine.

Food Processing Equipment

In case you work in the food and beverage industry, then you should know that most of the equipment that you use is made from stainless steel. The type 17-4 PH stainless steel is used in equipment for the processing and manufacture of foods and beverages.

The fact that the alloy has a good surface condition and great finish makes it an ideal choice. The alloy’s smooth surface and high chromium content make it less prone to corrosion and makes it easy to clean as hygiene is an integral element of food and beverage manufacture.

Type 17-4 PH Stainless Steel in the Oil and Gas Industry

Did you know that the alloy is a significant part of the oil and gas industry? There are two main reasons why the alloy is used:

First, Oil is usually obtained at great depths, below sea level. Such depths are associated with high pressure. The high strength of type 17-4 PH stainless steel makes it a great construction material for piping at such depths.

Second, Type 17-4 PH alloy is resistant to corrosion both on and offshore. Its resistance to corrosive media like hydrogen sulfide gas, carbon dioxide and low pH levels in oil prospecting conditions makes it the material of choice for oil rigs and pipes.

Conclusion

It is quite evident that type 17-4 PH stainless steel is the most used type of PH stainless steel. It has an ideal combination of corrosion resistance, good mechanical properties at high temperatures and high yield strength. This combination makes it a suitable alloy for many applications. Its superior properties and cost effectiveness makes it the best, most used type of stainless steel.

Is its good for very expensive materials like

Is its good for very expensive materials like

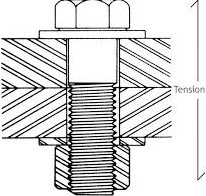

should be 8.2 ft-lb. Using a hydraulic bolt tension calibrator you test a bolt at this torque only to find that it doesn’t give you the required tension of 84 ksi; due to your conditions you are only getting a tension of 78 ksi. Now you use the calibrator to learn what torque you will need to apply to that bolt in order to give you the needed tension of 84ksi.

should be 8.2 ft-lb. Using a hydraulic bolt tension calibrator you test a bolt at this torque only to find that it doesn’t give you the required tension of 84 ksi; due to your conditions you are only getting a tension of 78 ksi. Now you use the calibrator to learn what torque you will need to apply to that bolt in order to give you the needed tension of 84ksi.

Torque is simply the effort (force) you apply to turn the bolt in place. When you apply the torque, it stretches the threads of the bolt and nut together. This “stretch” or elongation of the threads is called tension. It is tension that holds everything in place. Tension is critical in securing a bolt properly. If the tension is too week then the fastener could loosen; if it’s too tight the threads may be stripped or the bolt break.

Torque is simply the effort (force) you apply to turn the bolt in place. When you apply the torque, it stretches the threads of the bolt and nut together. This “stretch” or elongation of the threads is called tension. It is tension that holds everything in place. Tension is critical in securing a bolt properly. If the tension is too week then the fastener could loosen; if it’s too tight the threads may be stripped or the bolt break.